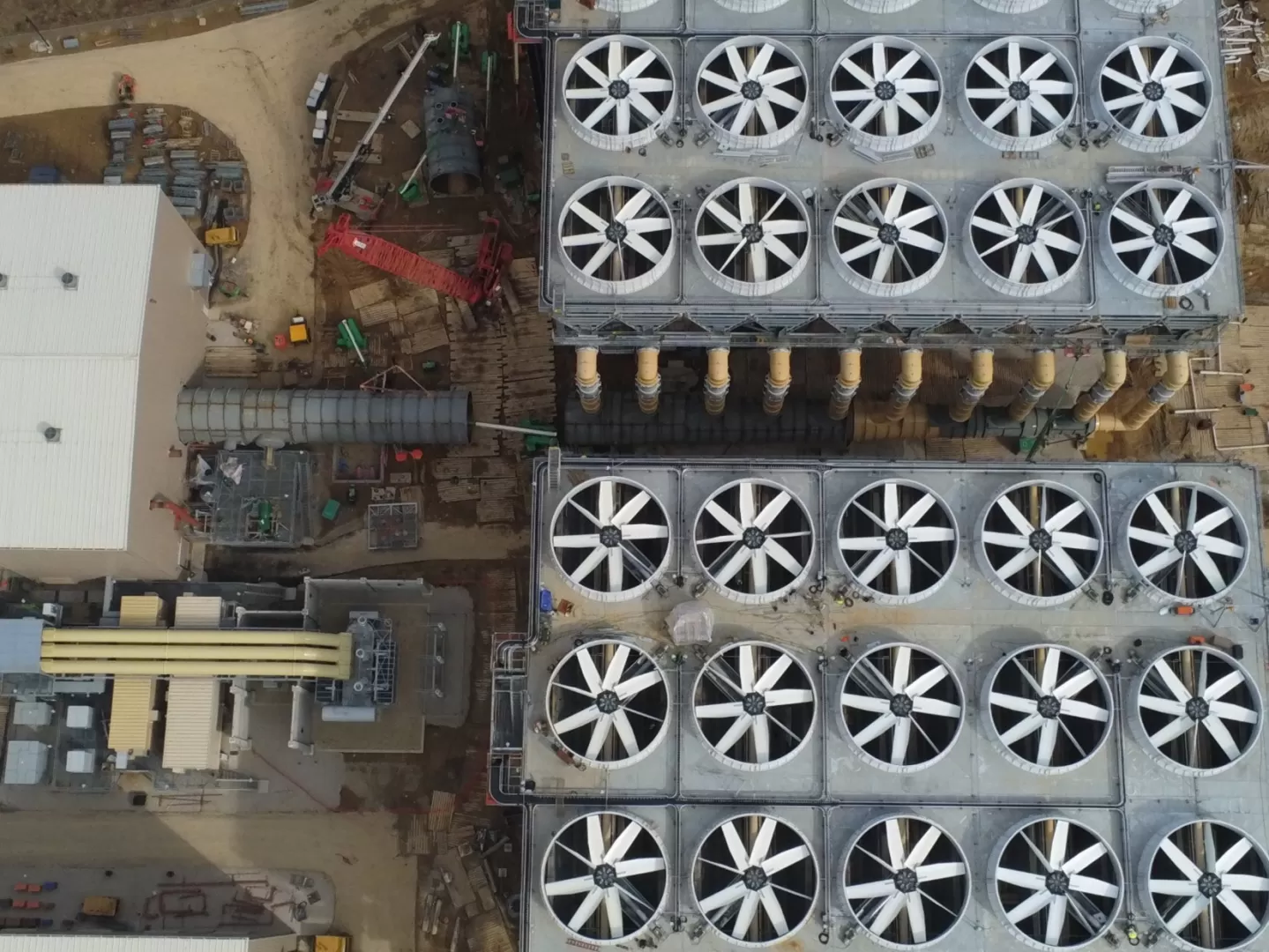

GUERNSEY POWER STATION ACC ERECTION

G.A. West was contracted by SPG Dry Cooling to perform the erection of the Air Cooled Condensers at Guernsey Power Station in Byesville, OH. The Air Cooled Condenser units, engineered and supplied by SPG Dry Cooling, were to be the first of a new design featuring a “W” shape rather than the traditional “A Frame”. Each unit consisted of a separate steel understructure, turbine exhaust ducting, tube bundles, steam manifolds, structural steel fan decks, 36 foot diameter fans, air removal piping, condensate piping, and cooling water piping.

All permanent materials were furnished by SPG and procured overseas. G.A. West was responsible for receiving, unloading, inventorying, storing, and shipping all items from a separate laydown facility to the project site. Each “W” section consisted of 12 tube bundles welded to 2 foot diameter steam manifolds within a jig. 150 of these “W” sections were preassembled and set onto 6’-6” diameter steam manifolds and welded into place.

Steel fan decks were preassembled and set atop the “W” sections. Each fan deck assembly consisted of steel framing, checkered plate, fan blades, fan gearbox, fan motor, and fan shroud. 60 fan deck assemblies were preassembled and set atop modules at ground level. The unit was constructed utilizing a modular approach created by G.A. West. Each module consisted of two complete fan cells inclusive of two fan decks, 5 “W” sections, and interior piping. 30 modules were assembled at ground level, with each having dimensions of 50 feet in width, 100 feet in length, 25 feet in height, and a weight of 535,000 pounds.

These modules were lifted and set in place atop the structural steel at an elevation of 75 feet. G.A. West designed and utilized a jig for the assembly of the ducting into spool pieces. Each piece consisted of three to six segments approximately 30 feet in length. The G.A. West designed jig features removable inserts that can be bolted to the jig for differing diameters of duct. The turbine exhaust ducting varies in diameter from 19’-8” down to 6’-6”. Piping diameters varied from 28” down to ½”. Once complete with an entire unit, the system was filled with compressed air and tested with a hold time of four hours.

BLACK & VEATCH LOWMAN ENERGY CENTER

G.A. West completed the civil portion of the Lowman Energy Center Combined Cycle project in Leroy, AL. The scope consisted of cutting and filling the project site to grade, installation of storm drain, underground utilities, and duct banks as well as the foundations.

We also conducted all of the underground electrical raceway for the new build of a 640 MW natural gas power plant.

BLACK & VEATCH BARRY 8 SUBSTRUCTURES

G.A. West completed the civil portion of the Barry 8 Combined Cycle project in Bucks, AL. The scope consisted of cutting and filling the project site to grade, installation of storm drain, underground utilities, and duct banks as well as the foundations.

G.A. West also completed all of the underground electrical raceway for the new build of a 720 MW natural gas power plant.

GEORGIA POWER PLANT SCHERER

G.A. West performed miscellaneous Design Change Notice work associated with the completion of the Units 1-4 Scherer SCR/FGD Environmental Project. This work scope consisted of numerous miscellaneous work scopes in SCR and FGD areas. A few notable work scopes included the installation of equipment and damper monorail systems in all SCR units, installation of SCR duct air cannons, and the installation of a backup makeup water piping system to service all four units.

G.A. West also performed the Units 1&2 FGD Completion Scope of Work. This scope consisted of the installation of the following items around the Advatech Single Tower Absorbers: limestone slurry bypass tank, limestone slurry feed pumps, limestone slurry fiberglass feed piping, oxidation air equipment, oxidation air stainless and fiberglass piping, jet air sparger (JAS) piping, recycle pump equipment, and recycle pump large bore fiberglass suction/discharge piping.